| Power | 140MW |

| Location | Manaus, Amazonas, Brazil |

| Partnership | GENRENT DO BRASIL / TECMON |

| Period | JUNE / JULY / AUGUST – 2010 |

The challenge

Rapid growth of population in Manaus, the significant regional economic growth and industrial development, combined with the district's distance from the Brazilian electricity grid, resulted in large energy shortage. Due to this lack of sufficient energy supply, local population faced with continuous power disruptions and distribution difficulties.

In order to restore power supply reliability, maintain the regional economic growth and industrial development and meet the power demand, which at the time was increasing by 7% per year, an emergency power solution was required. The local government issued emergency tenders for the supply, construction and operation of emergency power plants for variable periods. GenRent won the first tender as well as additional tenders and now provides over 25% of the power consumption in Manaus.

Our Rapid, Cost-Effective Solution

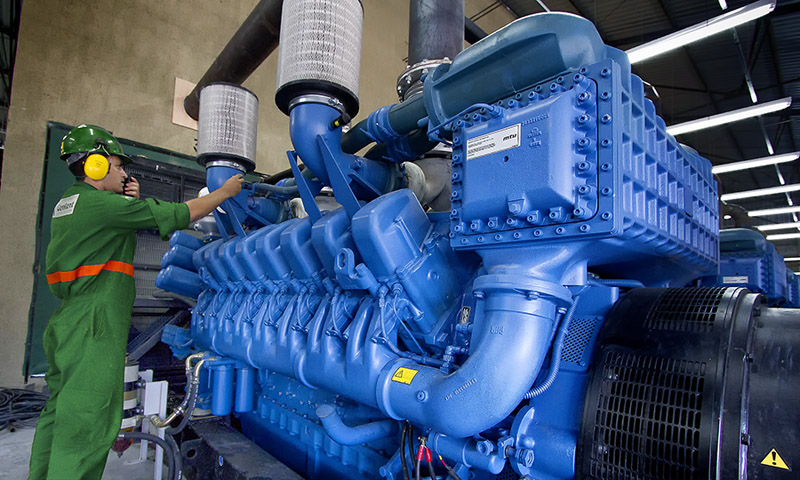

GenRent planned, constructed and commissioned a 140 MW primary (continuous) gas and diesel power plant, including equipment transportation and construction of a 69KV Substation, all within a record-breaking period of 3 months. GenRent also supplies ongoing operation and maintenance services for this power plant.

Civil

- earthwork and ground compression

- casting of concrete floors and creating paved areas

- construction of two 3000m² brick depots with metal roof and side doors for the accommodation of the power stations

- these brick depots include noise levels reducers

- assembly of the water, fuel and sewage system (including a system drinking water, sewage, rain and oily water drainage, separation boxes for water and oil)

- assembly of fire-fighting system (including pressurized hydrants, fire extinguishers, fire-fighting foam system, fire alarm system)

- Construction of the brick control and administration center

Mechanical

- assembly of 1.500m3 and 10m3 fuel tanks

- assembly of carbon steel pipe line for interconnection and supply of fuel oil, lubrication oil and water and oil separation systems

- assembly of Fuel pumps, exhaustion pipe line, fuel and lubricant filters, flow meters, purifiers and many more

Electrical

- the power plant is comprised of 110 diesel gensets, which together have a total capacity of 140MW

- assembly of equipment: 440VA-13.8KVA and 69KVA Step-Up Transformers, MV Protection Breakers, protection and power distribution boards

- assembly of outdoors 69KV Substation, including the construction and assembly of ground infrastructure and civil equipment, protection system, control system, bare copper cables, switches, insulators, lightning protection

- assembly of the electrical protection comprehensive system

- assembly of electrical command and supervision system: including the interconnection with the transmission grid, all through optical fibers and top of the line interfaces

- assembly of comprehensive communication system: for the purposes of communication between the power plant and the transmission grid's operational center, via satellite and via conventional system

- Advanced Control and Monitoring System: the power plant had to attend flexible demand and change of load, be remotely monitored and controlled, operate in conjunction with the power authority and interface with the specific client's protocol. The GenRent's SCADA base control system allows us as operators to monitor and control each generator in the power plant, including engine parameters, fuel system and all main circuit breakers in the substation

Environment Monitoring

- all our generation units as well as all the industrial residue process are monitored according to ABNT and CONAMA standards

- the gas emissions originating from the power stations fuel burning are monitored periodically and are in accordance with applicable law and standards

- the oily or non-oily residue emission is monitored periodically at the power plant exit point. The water and oil separation box is cleaned and monitored periodically as well

- in addition, noise levels are monitored to meet applicable regulation, with operational interventions whenever required