In light of the global trend of improved eco-balance, natural gas should increasingly be used for clean energy and replace other fossil fuels.

As a cleaner-burning fuel than HFO or diesel, natural gas power stations offer significantly cleaner emissions. GenRent develops and promotes the implementation of natural gas engines and turbines in power plants worldwide.

GenRent's natural gas power plant solutions are based on top-of-the-line technology from GE and MTU and include gas turbine power plants and gas generators. These cutting-edge solutions and equipment are the ideal answer to our clients' needs.

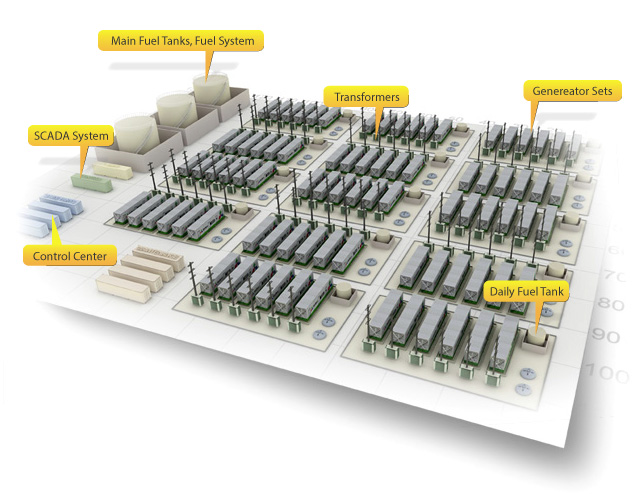

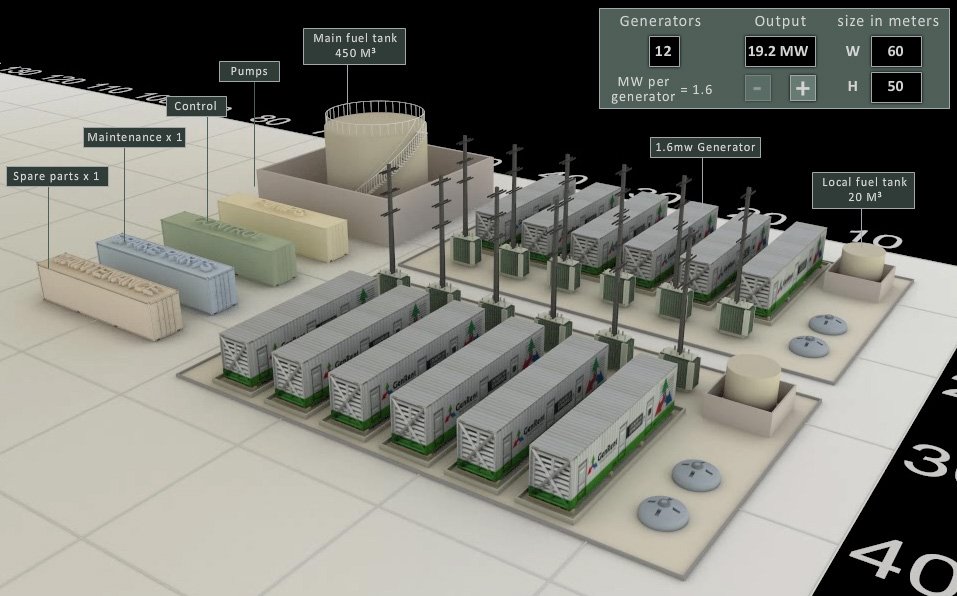

GenRent natural gas power plants deliver optimal power production across a wide range of peaking, intermediate and baseload usage scenarios. In highly-challenging global operating environments, GenRent's natural gas power plants provide robust performance and seamless cycle efficiency. Daily load fluctuations are handled easily with fast starts, stops and restarts for unmatched operational control.

GenRent offers two types of Natural Gas Temporary Power Plants:

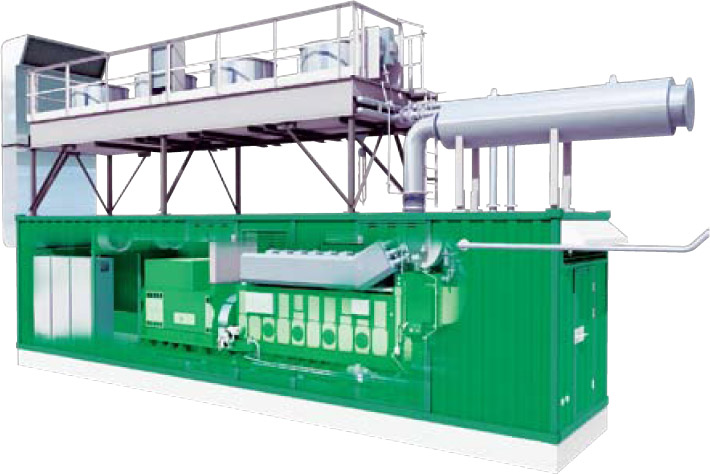

- Generators with gas engines - MTU Onsite Energy natural gas-powered cogeneration systems are technologically advanced solutions, which combine the highest performance with low emission values.

- Mobile Gas turbines - TM2500+ Trailer Mounted Aeroderivative Gas Turbine is ideal for providing a baseload bridge to permanent power installations or for generating backup power supporting natural disaster relief, plant shutdowns or equipment maintenance, the TM2500+ provides up to 30 megawatts.

All Power Plants supplied are delivered with a state-of-the-art Control and Monitoring system.

Whether emergency, continuous or prime power, whether for power generation alone or combined heat and power production (CHP), whether for governments, large industry or smaller private customers: GenRent develops economical and reliable system solutions specifically configured for individual applications.

GenRent natural gas power plant solutions offer numerous features and benefits, including:

- Lower financial risk and higher profitability of the client's investment

- High plant availability and multi-unit implementation for reduced backup requirements

- Power station net electrical efficiency in excess of 44%

- Robust plant performance in any conditions including hot and dry environments and high altitudes

- Optimal part-load efficiency

- 5-minute fast start up to full plant load from standby

- Closed-circuit radiator cooling for lowest possible water usage

- Low natural gas fuel pressure

- Maintenance requirements not dependent on number of trips or starts