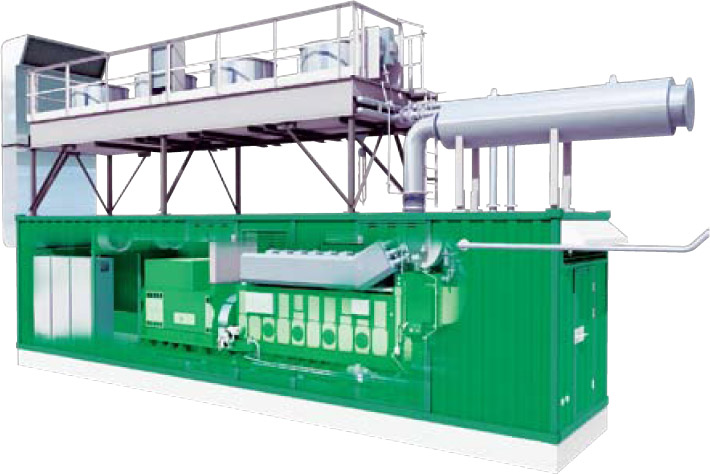

While gas-powered plants have many benefits, gas supply is not always easily available. For such cases, GenRent provides dual fueled power plants, with increased flexibility, ideal solution for a lack of a fully secured gas supply.

The operation of dual fuel power plants combines gas and diesel. Using advanced dual fuel control system, GenRent's power plants are able to operate on a wide range of gas/diesel supply combinations – from 100%/0% to 30%/70% respectively.

GenRent dual-fuel power plants deliver the following benefits:

- Highly economical electricity generation - fuel cost savings and low operation costs

- Reduced gas emissions

- Reduced storage of fuel

- Total Flexibility – the precise control of diesel and gas metering ensures an optimal performance under all operation conditions, even if no gas is available

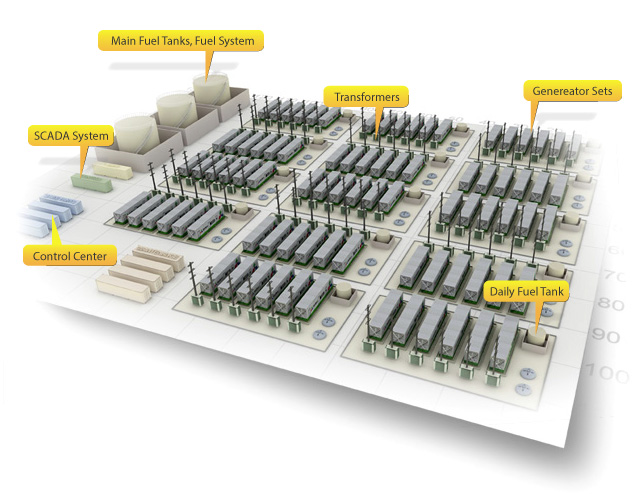

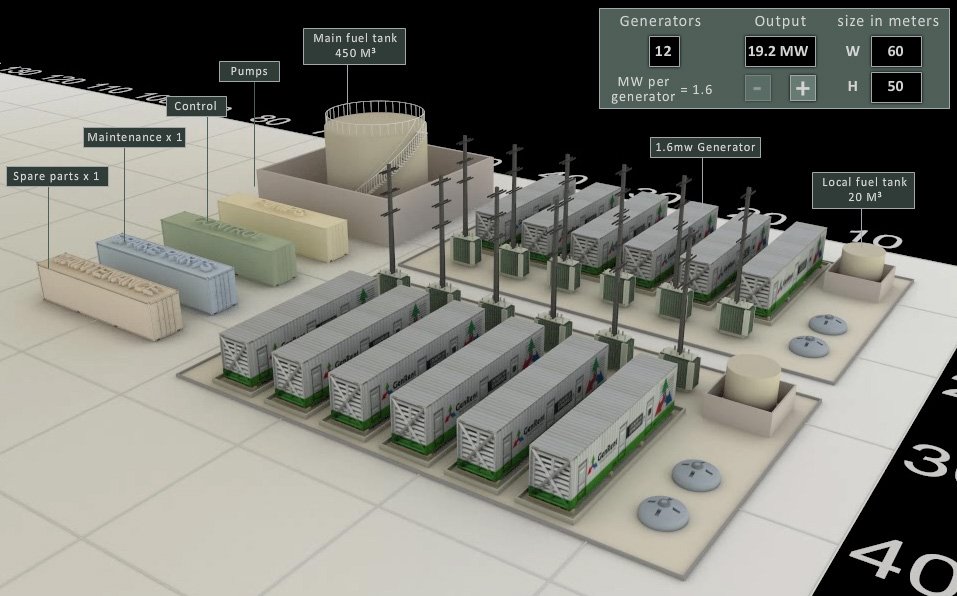

In order to offer its clients the optimal solution tailored to its specific needs and the project specifications, while ensuring minimal costs, GenRent maintains strong cooperation with different engines suppliers.

GenRent is working with the following suppliers:

- Komatsu Engines

- MTU Engines

All Power Plants supplied are delivered with a state-of-the-art Control and Monitoring system.

GenRent dual-fuel power plants feature:

- Applicability for different gas qualities such as natural gas, sewage gas and landfill gas

- Separate governor settings for diesel, gas and transfer mode

- Fixed or variable (load dependent) diesel-gas fuel combination

- Advanced diesel-gas mode transfer sequences

- Diesel assistance to backup gas mode

- Automatic mode selection depending on current conditions

- Automatic switch to diesel mode operation if gas supply fails

- Gensets less sensitive to high temperature and operate within a wide range of temperature and humidity